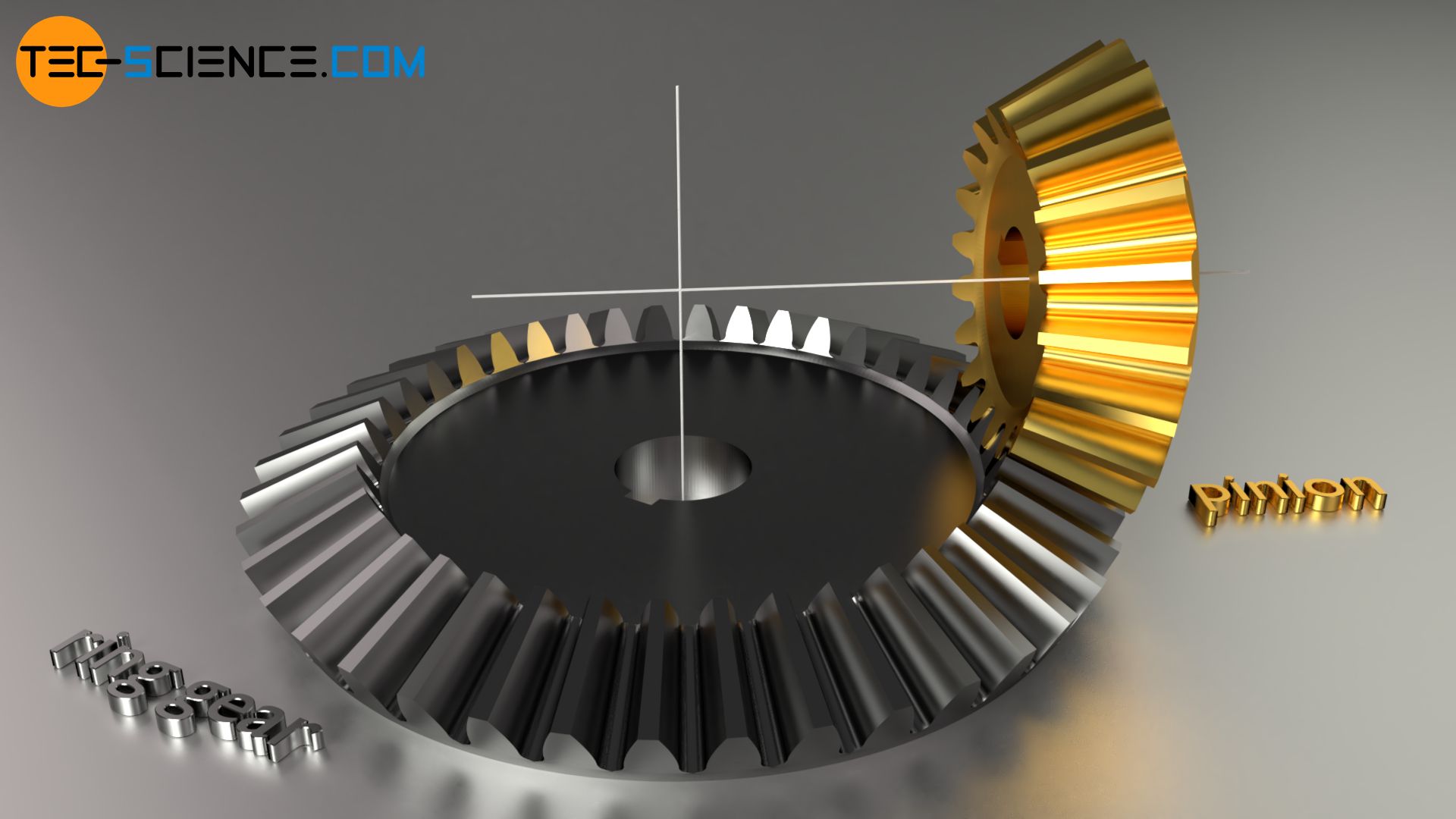

Surface defect detection and dimension measurement of automotive bevel gears by manual inspection are costly, inefficient, low speed and low accuracy. In order to solve these problems, a synthetic bevel gear quality inspection system based on multi-camera vision technology is developed. The system can detect surface defects and measure gear dimensions simultaneously. Three efficient algorithms named Neighborhood Average Difference (NAD), Circle Approximation Method (CAM) and Fast Rotation-Position (FRP) are proposed. The system can detect knock damage, cracks, scratches, dents, gibbosity or repeated cutting of the spline, etc. The smallest detectable defect is 0.4 mm × 0.4 mm and the precision of dimension measurement is about 40–50 μm. One inspection process takes no more than 1.3 s. Both precision and speed meet the requirements of real-time online inspection in bevel gear production.

TCL 40 NXTPAPER, Full-color Electronic Paper Display

Sensors, Free Full-Text, Pantograph

Sensors, Free Full-Text, mini box ribeiro

Random Nerd Tutorials Learn ESP32, ESP8266, Arduino, and Raspberry Pi

Sensors, Free Full-Text, mini box ribeiro

Sensor Text png download - 512*512 - Free Transparent Sensor png Download. - CleanPNG / KissPNG

Sensors, Free Full-Text, mini box ribeiro

Mini 3 Color Sensor – Nix Sensor Ltd

Sensors, Free Full-Text, underground roleplay download

Sensors, Free Full-Text

Sensors, Free Full-Text, condo games generator

α9 III full-frame camera with a global shutter system

Sensor Images - Free Download on Freepik

Sensors, Free Full-Text