Unit Size Net Weight Pint Kit 2 lb Gallon Kit 18 lb Five Gallon Kit 90 lb Mold Star rubbers are easy to use platinum silicones which are mixed 1A:1B by volume (no weighing scale necessary). Mold Star silicones feature relatively low viscosities and vacuum degassing is not required for most applications. Mold Star silicones cure to soft, strong rubbers which are tear resistant and exhibit very low long term shrinkage. Molds made with Mold Star will last a long time in your mold library and are good for casting wax, gypsum, resins, concrete and other materials. Cured Mold Star rubber is heat resistant up to 450F (232C) and is suitable for casting low-temperature melt metal alloys. Note: THI-VEX is NOT compatible with Mold Star rubbers. Note: This product will not work with modeling clays containing sulfur under

Unit Size

Net Weight

Pint Kit

2 lb

Gallon Kit

18 lb

Five Gallon Kit

90 lb

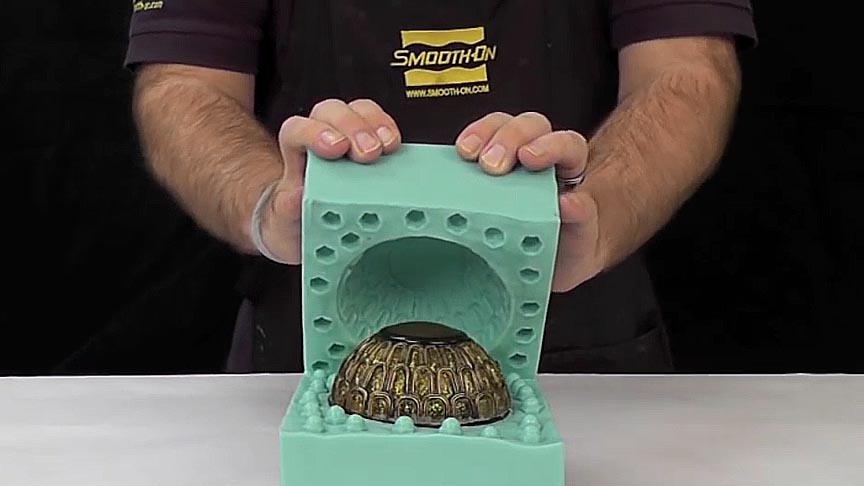

Mold Star rubbers are easy to use platinum silicones which are mixed 1A:1B by volume (no weighing scale necessary). Mold Star silicones feature relatively low viscosities and vacuum degassing is not required for most applications. Mold Star silicones cure to soft, strong rubbers which are tear resistant and exhibit very low long term shrinkage. Molds made with Mold Star will last a long time in your mold library and are good for casting wax, gypsum, resins, concrete and other materials. Cured Mold Star rubber is heat resistant up to 450F (232C) and is suitable for casting low-temperature melt metal alloys. Note: THI-VEX is NOT compatible with Mold Star rubbers. Note: This product will not work with modeling clays containing sulfur under any circumstances.Guide to Making Silicone Molds from SLA 3D Printed Models

Properties

Technical Properties

Mix Ratio by Weight

1A:1B

Mix Ratio by Volume

1A:1B

Pot Life

50 minutes

Cure Time

4 hours

Color

Green

Shore Hardness

15A

Mixed Viscosity

12,500 cps

Shrinkage

< .001 in./in.

Specific Volume

23.5 cu. in./lb.

Specific Gravity

1.18g/cc

Useful Temperature (max)<

450F

Useful Temperature (min)<

-65F

Tensile Strength

400 psi

100% Modulus

55 psi

Elongation @ Break

440%

Die B Tear Strength

88 pli

Media

CASTING A SILICONE MOLD USING MOLD STAR SERIES SILICONES

Documentation

Technical Bulletin

Related Products

RELATED PRODUCTS:

Mixing Equipment

Silc Pig Silicone Pigments

Ignite Fluorescent Colorants

Ease Release 200

Ease Release 205

FormX Webshop

Smooth-On - Smooth-Cast 300 Liquid Plastic Compound & Mold Star 15

Mold Star™ 15 SLOW Product Information

FormX Home

Video - 2-Part Mold Star™ 15 Mold

Mold Star 15 Slow – купить в интернет-магазине OZON по низкой цене

Smooth On Fabrix 3D

Smooth-On Mold Star 15 Slow: Detailed Moulds

Mold Star 30 Pint Kit - 900gm

Testing ways to prevent cure inhibition in platinum silicone, when

Mold Star 15 platinum silicone demo and review

Mold Star 15 Slow - 1A:1B Mix by Volume Platinum Singapore

Mold Star™ 15 SLOW Stir Part A + Stir Part B

Mold Star 30 Pint Kit - 900gm

Making Your Own Hyper-Realistic Finger Corals Using Mold Star