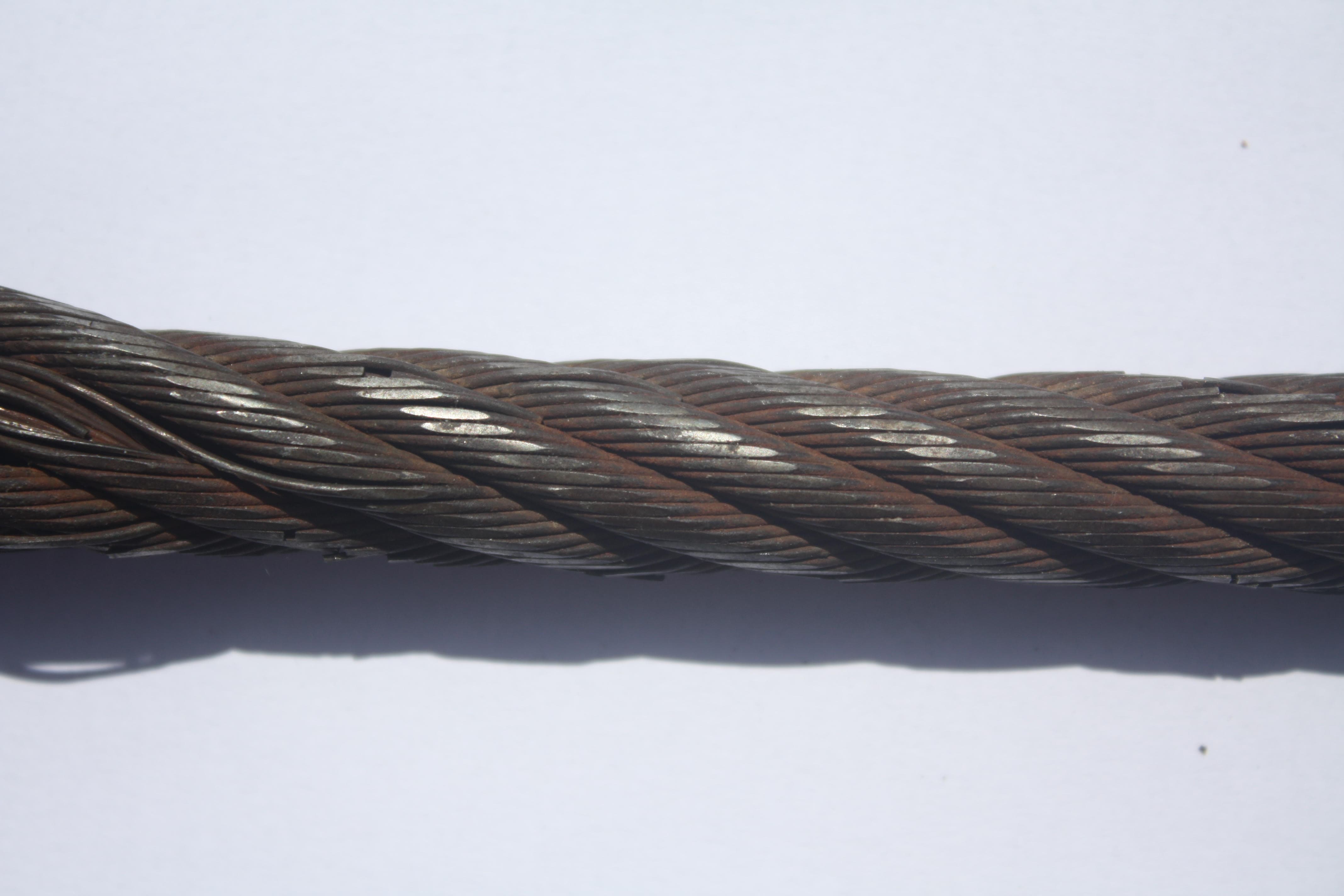

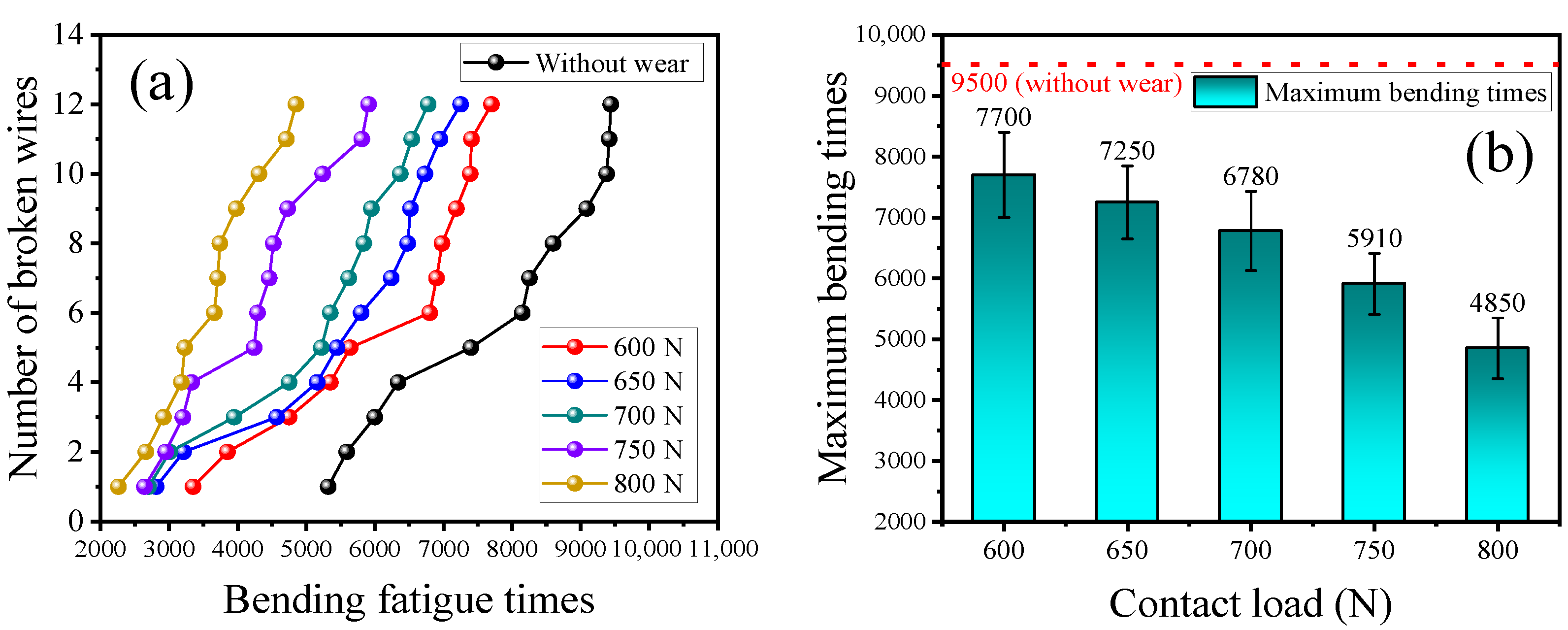

Surface wear caused by contact between crane wire rope and a pulley seriously affects the mechanical properties of the wire rope. In this study, the tribological behavior of wire rope was investigated using a homemade rope–pulley sliding friction test rig. Then, the influence of different surface wear on the bending fatigue life of the rope samples was analyzed. The results show that the friction coefficient (COF) decreases with the increasing sliding distance. It reaches a minimum of approximately 0.52 when the contact load is 700 N. The surface temperature of the wire rope rises rapidly and then gradually stabilizes. The maximum temperature rise fluctuates in the range of 50 °C to 60 °C with increasing contact load. The wear scar of the wire rope is irregular, and the maximum wear width increases from approximately 1.94 mm to 2.45 mm with the contact load. Additionally, increased contact load leads to smoother wear surface of wire rope, and the wear mechanisms are mainly abrasive wear and adhesive wear. Additionally, surface wear leads to a decrease in the bending fatigue life of wire ropes, and degradation of anti-bending fatigue is more serious under a larger sliding contact load.

Blaster 11 oz. PB Penetrating Oil (Pack of 6) 16-PB-DS - The Home Depot

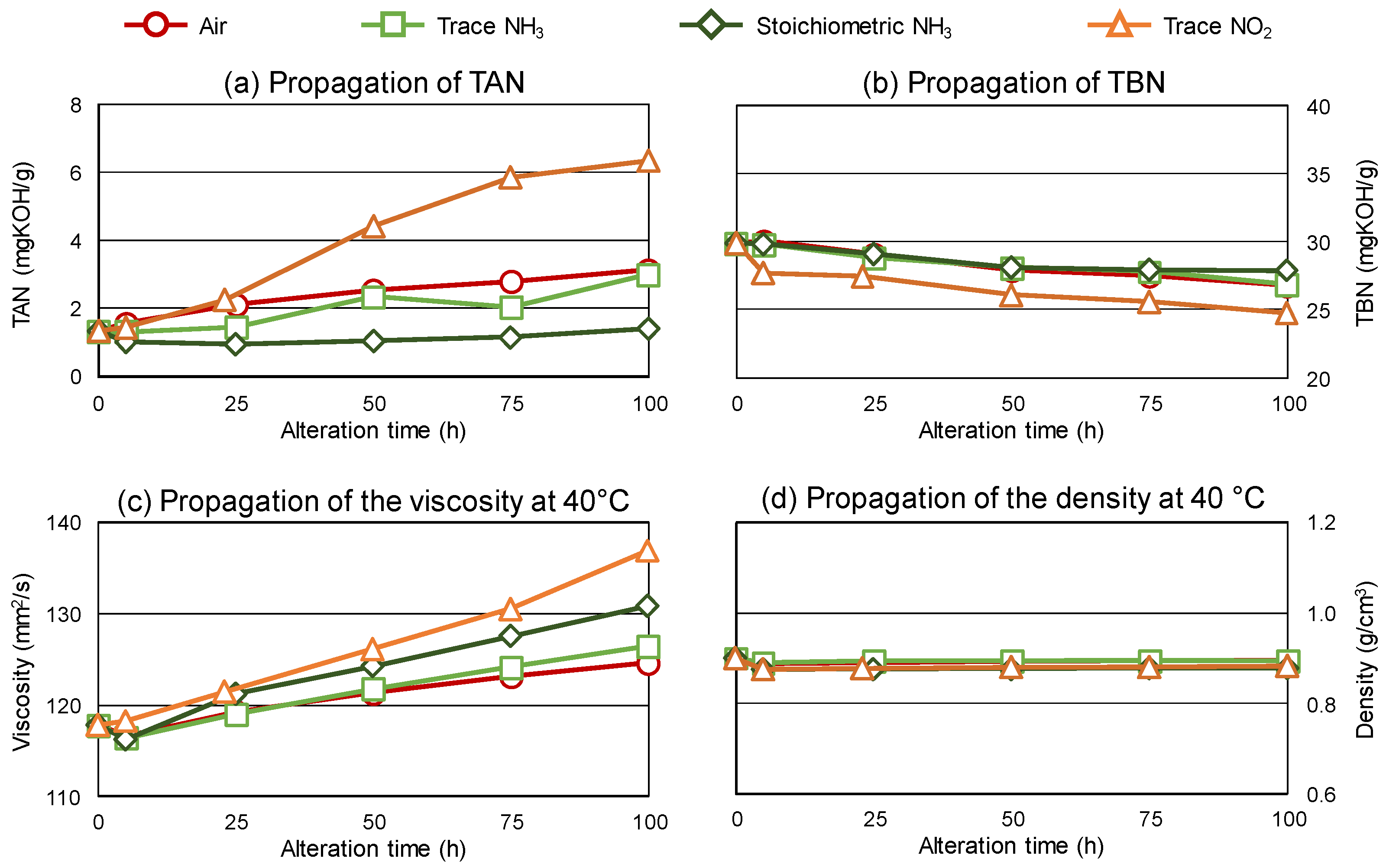

Lubricants, Free Full-Text

Lubricants, Free Full-Text

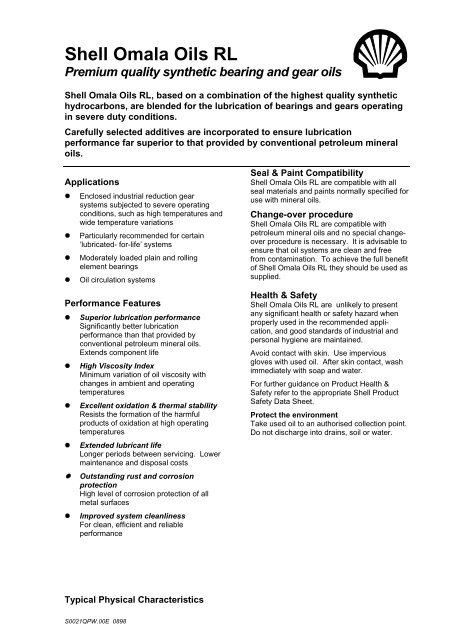

Shell Omala Oils RL - Parsian Super Lubricants

Solvent-free covalent MXene nanofluid: A new lubricant combining the characteristics of solid and liquid lubricants - ScienceDirect

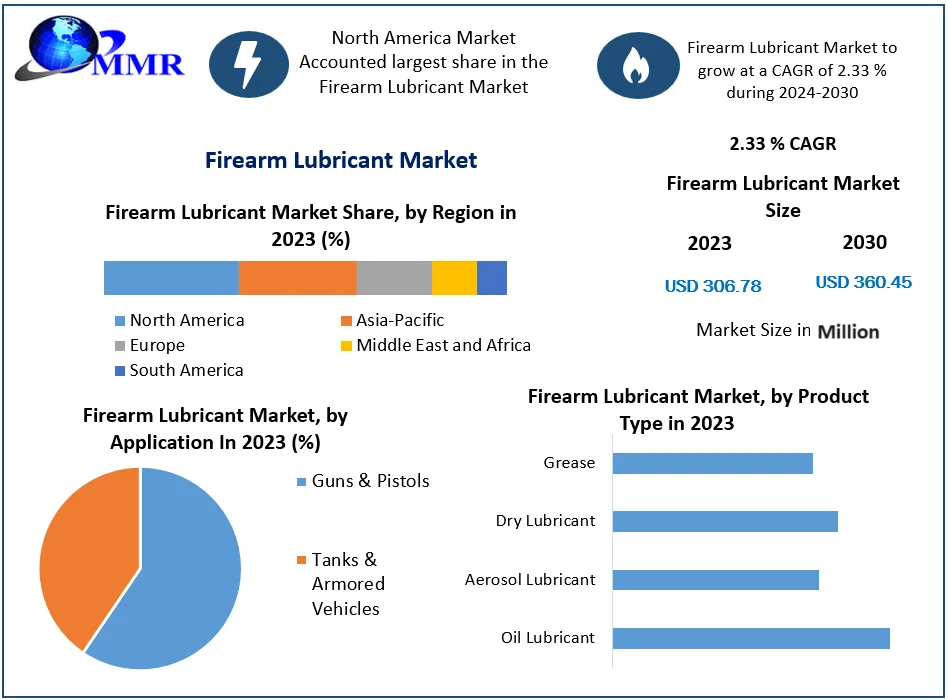

Firearm Lubricant Market: Industry Analysis and Forecast

Free samples BodyGliss Lubricants

TROJAN Lubricant H2O Closer Water Based Lubricant, Personal Lubricant, 5.5 fl oz

PDF) A critical review on vegetable oil-based bio-lubricants

Lubricants, Free Full-Text