In mechanical design, the black anodizing process is often performed on the surface of the aluminum part. Generally, black anodizing is a process that first

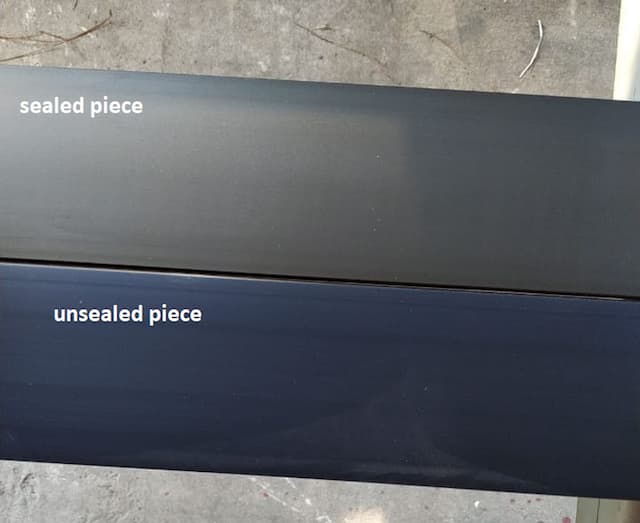

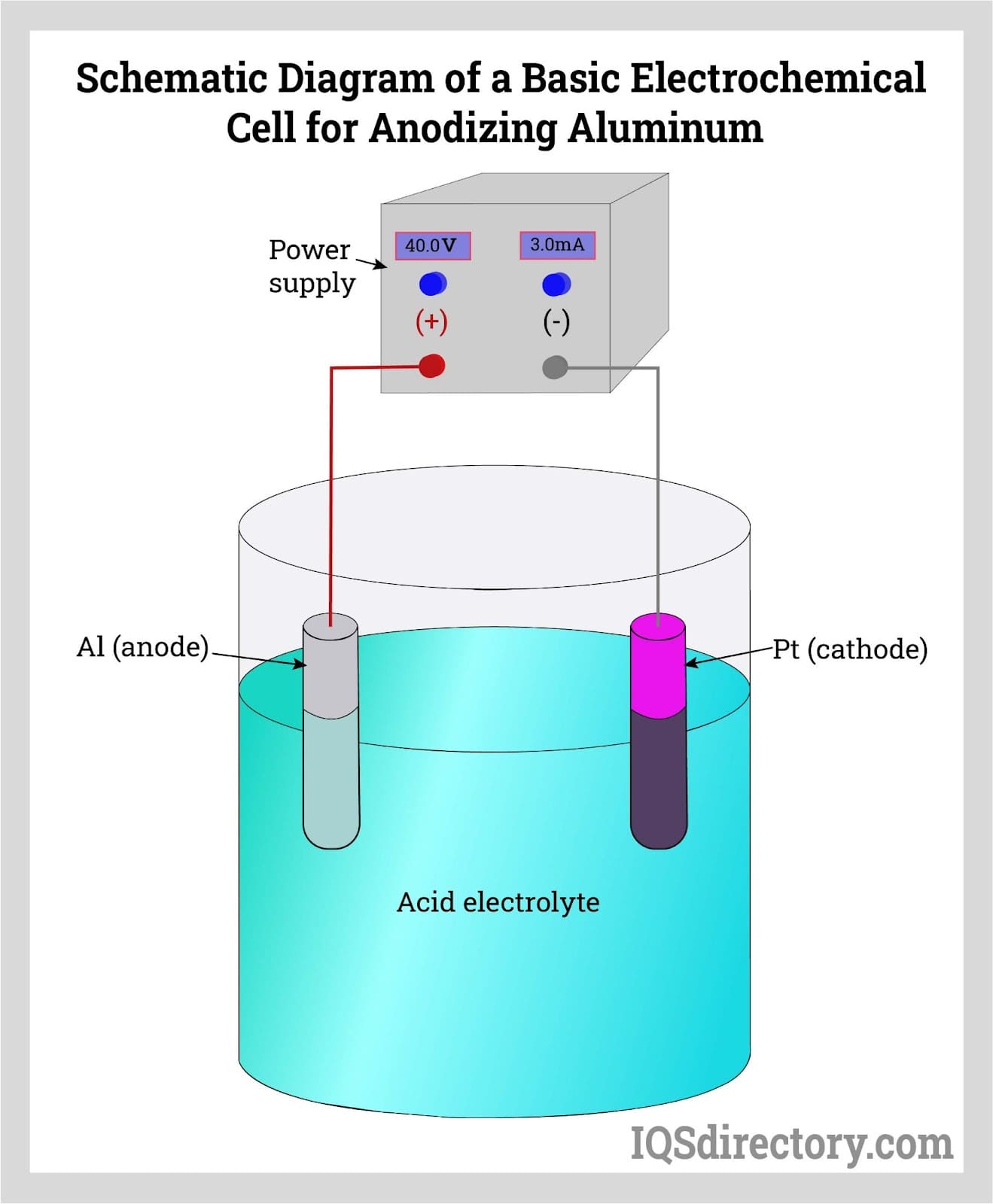

In mechanical design, the black anodizing process is often performed on the surface of the aluminum part. Generally, black anodizing is a process that first anodizes an aluminum part and then dyes it black with an appropriate dye. Conducting black anodizing on an aluminum part can obtain an aesthetic or functional black color while enhancing its corrosion and wear resistance.

Learn More: The Anodizing Process Explained

Yoyo Z. on LinkedIn: The common types of brass grades include Alloy 260, Alloy 280, Alloy 360…

Anodized Aluminum Parts Basics: Process, Benefits, Design Tips, And Applications - LEADRP - Rapid Prototyping And Manufacturing Service

Two-step black anodizing Q&A, Problems & Solutions

Anodizing of aluminum and titanium materials

Black Anodized Aluminum for Industrial and Commercial Use - Zetwerk

What are the Properties of Black Anodized Finishes?

Black Anodized Aluminum - Die Casting Finishing- Sunrise Metal

Anodized Aluminum: Types, Uses, Features and Benefits

Surface Finish - LEADRP - Rapid Prototyping And Manufacturing Service

Di Zhang on LinkedIn: How to Choose the Right CNC Machine Shop? 1. Competitive Pricing Machine…

Black Anodized Aluminum Basics: Understanding Black Anodizing Process - LEADRP - Rapid Prototyping And Manufacturing Service